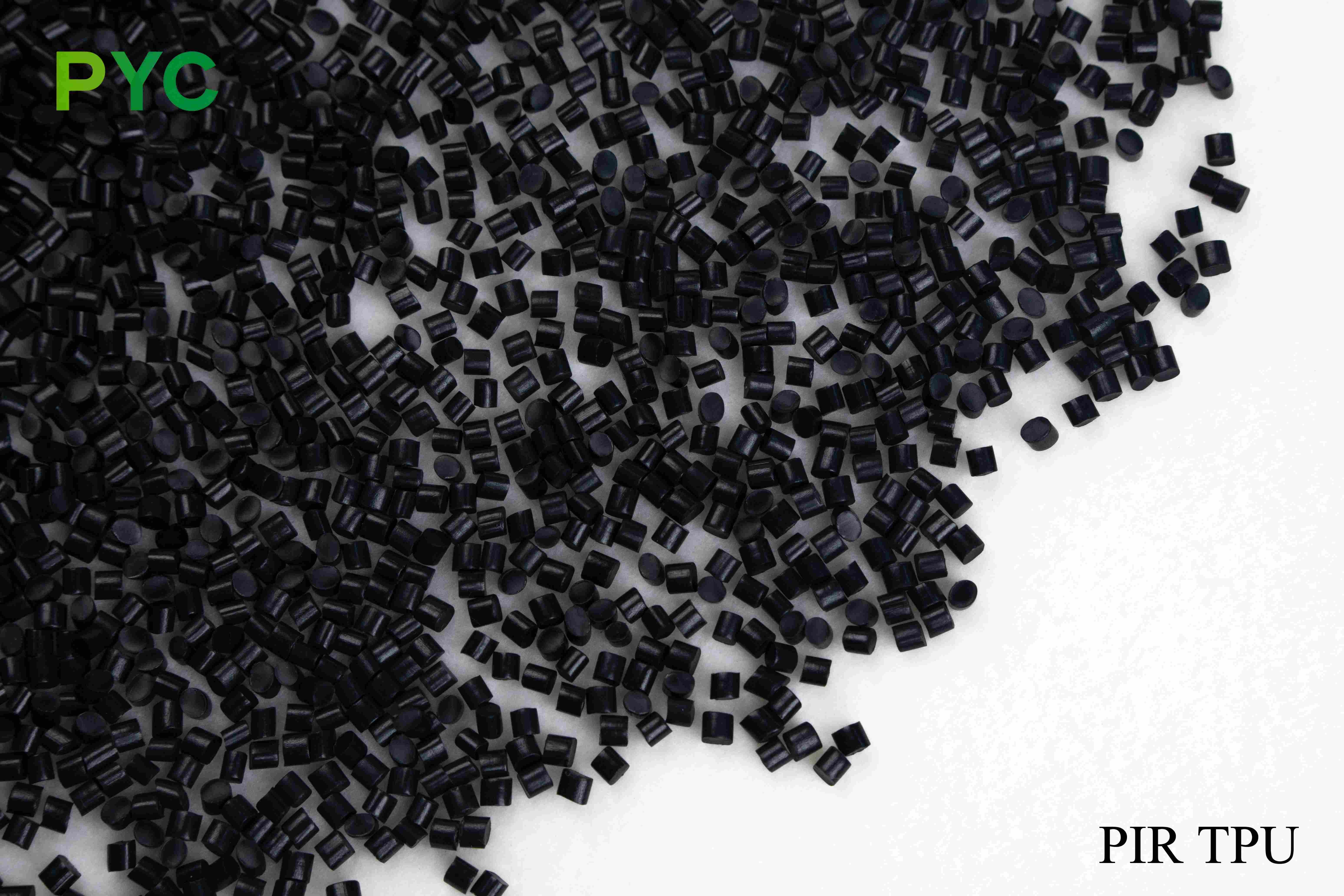

TPU PIR

PIR TPU (Poliuretano Termoplástico Reciclado Postindustrial) - Poliuretano termoplástico reciclado postindustrial

El PIR TPU es un plástico ecológico fabricado mediante el reciclaje de residuos de poliuretano termoplástico (TPU) procedentes de procesos de producción industrial. El poliuretano termoplástico posee excelente elasticidad, resistencia al desgaste, al impacto y a los productos químicos, y se utiliza ampliamente en las industrias automotriz, electrónica, médica, del calzado y otras. Al reciclar las materias primas de TPU desechadas, el PIR TPU no solo reduce la demanda de materias primas, sino que también contribuye a reducir la acumulación de residuos plásticos, en consonancia con los objetivos de desarrollo sostenible y producción ecológica.

Product Details

1. High-quality recycled feedstock sources

PIR TPU's recycled raw materials are mainly derived from waste thermoplastic polyurethane materials from industrial production, including:

Production waste: such as TPU injection molded parts, extruded materials, edges and corners.

Waste plastic products: e.g. waste TPU parts, packaging films, shoe soles, etc.

Waste products: such as discarded TPU belts, industrial hoses and transmission parts.

These recycled materials are rigorously screened, cleaned and processed to transform them into high-quality PIR TPU raw materials, ensuring excellent performance in different applications.

2. Strict quality control

PIR TPU undergoes comprehensive quality control during the production process, ensuring that its performance meets industry standards by testing a number of indicators, including tensile strength, hardness, elasticity, impact resistance, abrasion resistance, and chemical resistance. Each batch of recycled material is carefully processed to ensure the consistency and reliability of the material.

3. Excellent performance

High Elasticity and Flexibility: PIR TPUs are extremely elastic and remain flexible even at low temperatures, making them suitable for applications requiring high elasticity.

Abrasion resistance: PIR TPUs have excellent abrasion resistance and are particularly suitable for sports shoes, conveyor belts and other parts where abrasion resistance is important.

Strong Impact Resistance: PIR TPU has excellent impact resistance and is able to maintain its shape and not break easily when subjected to impact and pressure.

Chemical and oil resistance: PIR TPU is highly resistant to a wide range of oils, solvents and chemicals for use in harsh chemical environments.

Temperature resistance: PIR TPU has good high temperature resistance and is suitable for applications in both high and low temperature environments.

4. Environmental protection and sustainability

PIR TPU is a recycled material. Production from recycled TPU scrap reduces the need for raw materials, lowers plastic waste emissions and meets environmental and sustainability goals. The recycling process saves energy, reduces carbon footprint and is an important part of green production.

5. Cost-effectiveness

The use of PIR TPU as a raw material has cost advantages over traditional new materials. Recycled materials not only reduce the cost of purchasing raw materials, but also reduce the energy consumption of production, which helps companies to reduce the overall production costs and improve market competitiveness.

Application area

Footwear industry: PIR TPU is widely used in the footwear industry, especially in the production of athletic shoes, work shoes, boots and other soles, providing good comfort, wear resistance and elasticity.

Automotive industry: Used in the manufacture of automotive interior trim parts, window seals, hoses and other components, PIR TPU has excellent weather resistance, wear resistance and elasticity, and is suitable for automotive high-load parts.

Electronic industry: In electronic equipment, PIR TPU is used for sheath of wire and cable, flexible connector, etc., with excellent electrical insulation and wear resistance.

Industrial applications: PIR TPU is also used to manufacture industrial parts such as transmission belts, seals, hoses, etc., providing good wear resistance and high temperature resistance.

Product Advantages

High elasticity and flexibility: The elasticity and flexibility of PIR TPU make it suitable for applications that require frequent bending or deformation, such as footwear and sports equipment.

Excellent wear resistance: The PIR TPU is very resistant to friction and is suitable for use in conveyor belts, soles and mechanical parts.

Strong impact resistance: PIR TPU shows high toughness when subjected to impact, and is widely used in parts that need to withstand external shocks.

Chemical resistance: PIR TPU has excellent resistance to oils, solvents and most chemicals, and is suitable for protection of chemical and mechanical equipment.

Environmental protection: PIR TPU uses recycled TPU waste, reducing the dependence on petroleum-based raw materials, in line with environmental protection and sustainable development requirements.

Production and technical advantages

Advanced recycling process: PIR TPU uses modern recycling technology to ensure that the quality and performance of recycled materials are close to new materials and meet the requirements of high-end applications.

Strong processing adaptability: PIR TPU can be processed by injection molding, extrusion, blow molding and other ways, which is suitable for different forms of product manufacturing.

Good processing performance: PIR TPU has good fluidity and formability in the processing process, and can achieve high-precision product production to meet the needs of different industries.